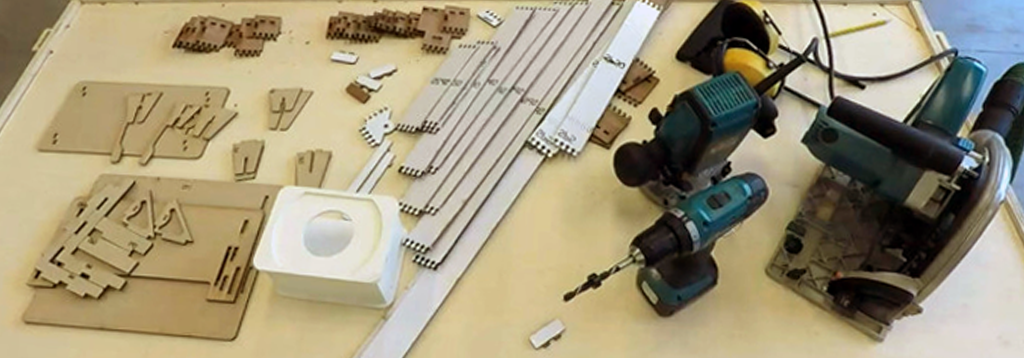

We present JigFab, an integrated end-to-end system that supports casual makers in designing and fabricating constructions with power tools. Starting from a digital version of the construction, JigFab achieves this by generating various types of constraints that configure and physically aid the movement of a power tool. Constraints are generated for every operation and are custom to the work piece. Constraints are laser cut and assembled together with predefined parts to reduce waste. JigFab’s constraints are used according to an interactive step-by-step manual. JigFab internalizes all the required domain knowledge for designing and building intricate structures, consisting of various types of finger joints, tenon & mortise joints, grooves, and dowels. Building such structures is normally reserved for artisans or automated with advanced CNC machinery.