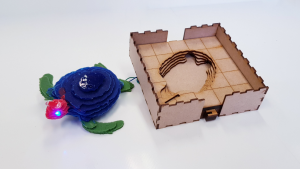

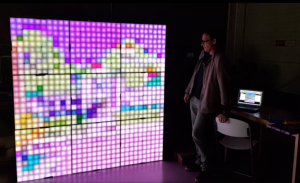

CHI 2024 – Designing Instructions using Self-Determination Theory to Improve Motivation and Engagement for Learning Craft

Recent HCI research has shown significant interest in investigating digital working instructions for guiding novices to perform manual tasks. While performance enhancement has been a

Send me an email “hello (a) dannyleen.be”

Send me an email “hello (a) dannyleen.be”